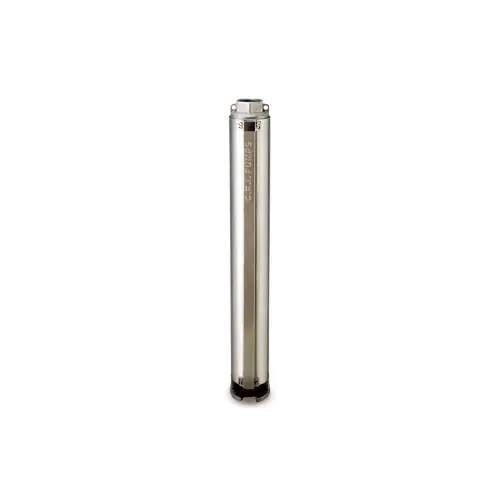

Borehole Pumps

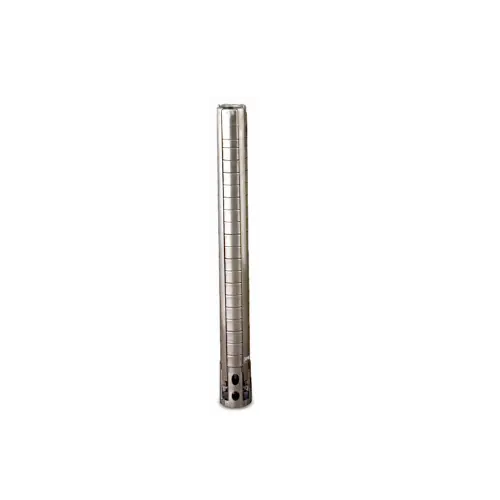

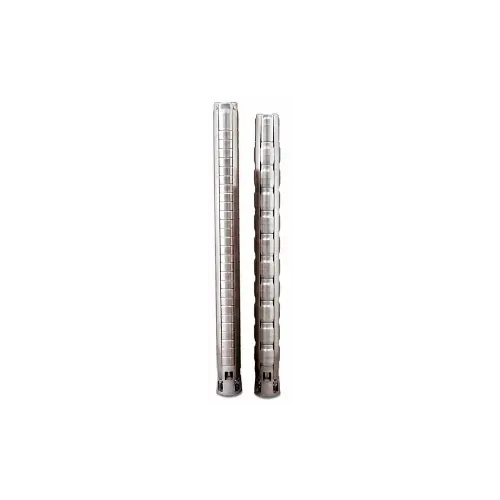

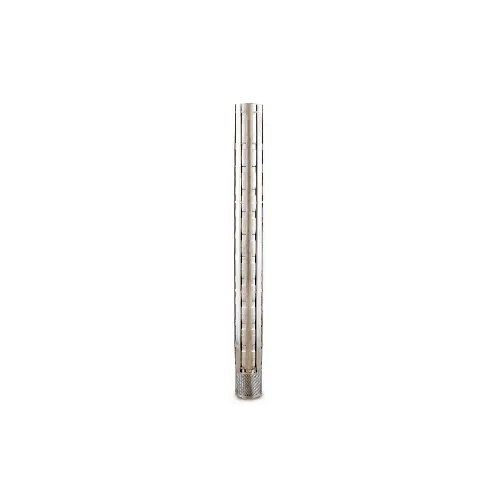

Borehole pumps are sophisticated submersible centrifugal pumps characterized by a multistage design, enabling them to operate effectively at significant depths. These pumps are specifically engineered to fit into narrow boreholes, which are drilled to access groundwater resources efficiently.

The motors utilized in borehole pumps are typically filled with water or oil to provide optimal lubrication for the bearings and are sealed with high-performance mechanical seals to ensure reliability. A cable exits the motor through a cable gland, with its length customized to accommodate the specific depth of the borehole.

Operational Mechanism of Borehole Pumps

The operation of a borehole pump is driven by a motor that rotates a shaft, which in turn drives one or more impellers within the pump assembly. The pump is strategically positioned above the motor, with the motor located at the bottom. This design features a central intake and a top discharge, distinguishing it from conventional pump configurations.

As fluid enters the first impeller, it is filtered through a suction strainer and directed to the diffuser, facilitating efficient fluid movement. In single-impeller configurations, the liquid flows around a non-return valve before exiting the unit. In contrast, multi-impeller designs allow the liquid to pass through several impellers, enhancing the overall performance before it exits through the non-return valve.

Applications

Borehole pumps are widely utilized across various sectors for applications such as drainage, irrigation, and the provision of potable water. Their robust design and efficient operation make them a critical component in sustainable water management solutions.